|

you have Guest user access (not logged in)

|

||

visitors since May 2003 ClubSite © ver 1.3 |

|

|

click here to return to the gallery list

|

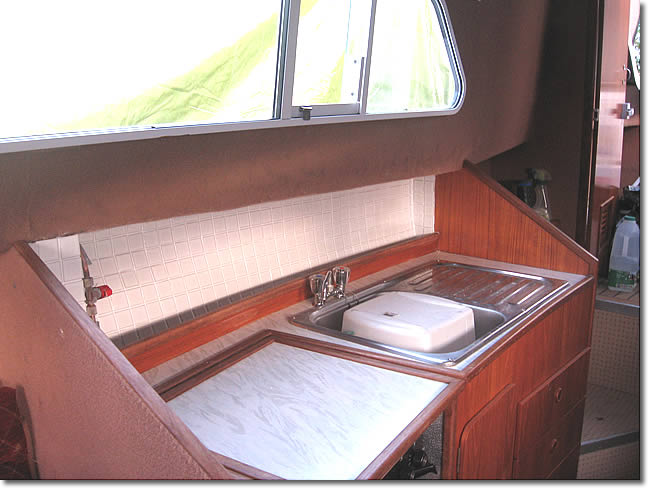

Tiled galley on 'Ice and a Slice' -

by Andy Mullins

|

|

The standard finish to the recessed splash-back area in the galley was carpet (this still appears to be the finish on the brand new models too). As we use this area for placing washing up liquid and the like, we wanted a finish that could be more easily wiped down and generally more hygienic than carpet. This basically included the back, sides and bottom of the recess. The solution we chose was to tile this area, as the materials are readily available, cheap and require only basic DIY skills to install. We went for mosaic tiles (approx 50mm x 50mm (2” x 2” in old money!)) as these are more likely to mould to the shape of the hull. We chose white tiles from B&Q and we needed just over two boxes (why do you never need just UNDER a full box!!). I removed the carpet from this area and found the inner surface of the hull in a most lumpy / bumpy state with loose strands of fibre and generally a poor surface to tile on. I cut off some of the individual lumps using a sharp chisel and sanded the rest. The next issue was how to stick the tiles to the GRP. I contacted BAL, who are one of the leading ceramic tile adhesive companies. They could offer me nothing that they would guarantee. The anticipated movement and deflection of the GRP to normal stresses and strains (including when she is brought out of the water in winter) and normal thermal movement was too much for them to accommodate, even with their ‘flexible’ adhesives. I took advice from a friend in the yachting world and he suggested using Sikaflex adhesive / caulking. This is a mastic type product that is applied using a normal mastic gun. It is very flexible and is designed to stick well to GRP and other materials. I duly purchased two tubes (expensive stuff at approx £10 / tube). I guess other products will do just as well, but I would avoid a lot of the DIY mastics, as these tend to go hard and brittle. As an alternative I would go for a Dow Corning silicone sealant. Our mosaic tiles have a fine hessian backing that holds them in a sheet approx 300mm x 300mm (12” x 12”). When I had a large enough area for a full sheet, this was laid upside down on the worktop and beads of mastic applied to each tile (not too much as you don’t want the mastic to squeeze onto the face of the tile). When all tiles have mastic applied, simply lift and position the sheet, gently pressing onto the GRP (don’t apply too much pressure – you need some thickness of mastic behind the tile for it to remain flexible. The adhesive grabbed quite well but strategic use of the odd matchstick came in handy until the adhesive dried (24 hours). Individual tiles were placed in the same manner, cut if required. I used about 1.5 tubes of the Sikaflex in all. After allowing the adhesive to set for 24 hours I tested the tiles. There was no way they were budging, but they were flexible. I finished off with a normal flexible tile grout and then applied a white silicone seal to the edges, having cleaned these joints first with methylated spirits. There is a word of caution when using the mastic adhesive – It gets everywhere! It doesn’t matter how careful I was, before long I was covered in it. I had a plenty of toilet roll, tissues, bin bags etc.. and tried to keep as clean as possible. Also put protection down on the floor and all adjacent surfaces.

To finish things off, I added an LED light under the bulkhead (I stuck this on with mastic as was worried about drilling into the hull for obvious reasons. This was held in place with masking tape until the mastic had set). We have now also stuck hooks on the tiles and hang some of our coffee mugs from them!! Finally, there is another added benefit. The weight of the tiles (which was actually not that much) helps trim our boat as all of the weighty items are on the port side. The tiles are now on the starboard side so must help!!! I applied the new tiles over Christmas 2007 and wanted to make sure the ceramic tiles did not cause a condensation problem too (the carpet naturally prevents this). Even during the cold spells we have had, I didn’t notice any problems there (I wonder if the mastic / air space behind actually insulates then a little).

All in all we are very pleased with the change and would recommend it to anyone. Regards Andy Mullins (Ice and a Slice) (Many

thanks to Andy for his kind permssion to include his © photos and

text on this site) |